Embossed Aluminium Foil Jumbo Roll

Unveiling the Versatility of Embossed Aluminum Foil Jumbo Rolls: Functions and Applications

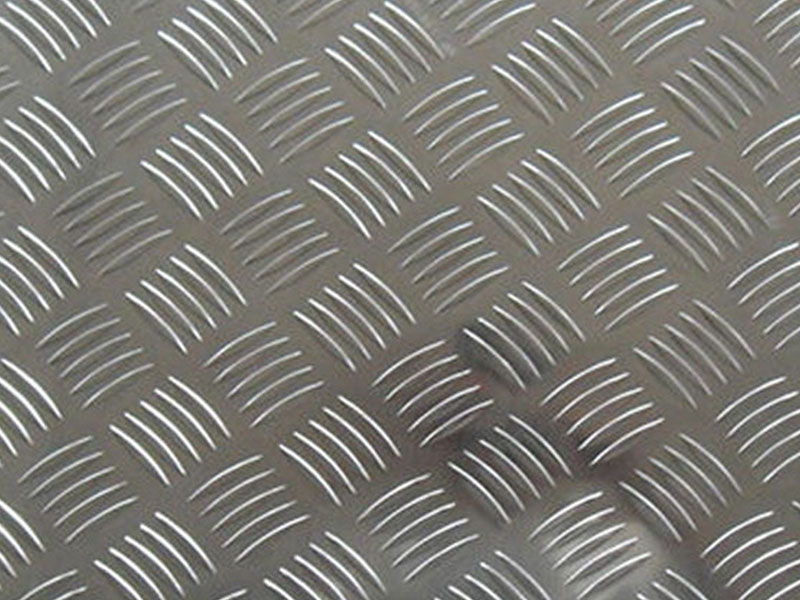

Aluminum foil is a mainstay across a multitude of industries, prized for its combination of lightweight durability and barrier properties. Among the many forms that aluminum foil can take, the embossed aluminum foil jumbo roll stands out for its unmatched versatility and utility. The original embossed texture not only enhances aesthetic appeal but also significantly increases the material's functionalities.

The Technical Details Behind Montounding Versatility

Embossed aluminum foil jumbo rolls are typically manufactured using a process that includes both thin rolling and stamping. The embossing process entails pressing raised patterns or designs into the soft, malleable aluminum sheet, increasing rigidity while reducing slip when rolled. The resulting foil is typically between 30 to 40 microns in thickness, maintaining a perfect balance of strength and flexibility.

From my perspective on the production floor, embossed aluminum foil jumbo rolls are the very foundation of our Stucco Embossed Aluminum Sheet. We receive them in colossal sizes, each roll weighing tons and presenting its own unique challenges. The consistency of the embossing is paramount; even slight variations across the roll can impact the final product's quality and lead to production slowdowns or even defects. We regularly inspect these jumbo rolls, meticulously checking for surface imperfections, thickness uniformity, and the depth and clarity of the stucco embossing itself. Any deviation necessitates careful attention, potentially requiring adjustments to our slitting and embossing machines to compensate. It's a constant juggling act between maximizing throughput and maintaining the high quality our customers expect.

Personally, I find the sheer scale of these jumbo rolls . Handling them requires specialized equipment and a high level of precision to avoid damage. Seeing the raw material transform from a seemingly endless coil of shiny foil into neatly-packaged sheets, ready for shipment, is deeply satisfying. It's a testament to the collective effort of our team and the sophisticated machinery we utilize. There's a certain artistry, too, in the subtle interplay between roll tension, embossing pressure, and the final aesthetic result. It's more than just manufacturing; it's a precise dance of engineering and craftsmanship.

One of the seamless ends of embossed aluminum foil is the retention phase during wrapping. Due to its raised patterns, this type of aluminum foil excels in ensuring that finished goods maintain their integrity during storage. The embossed surface helps thieves grip when unspooling or during heating applications, preventing the thin foil from tearing or breaking, a common challenge with smoother surfaces.

Lingering On the Benefits: Functions and Applications

-

Thermal Insulation and Protection: One prime function of embossed aluminum foil is its application as thermal insulation in diverse environments. Its unique embossed texture works to trap air pockets, creating a barrier against thermal conductance. Consequently, many industries including construction and packaging employ it to help maintain temperatures in food storage, significantly enhancing the product’s efficacy.

-

Protective Identifier: In addition to thermal properties, embossed foil plays a pivotal role as a protective identifier in goods stored for extended periods. The raised impression minimizes surface contact and guards against prevailing moisture, gases, and UV radiation, ensuring product longevity—forged foil thrives in harsh manufacturing environments.

-

Artistic and Promotional Usage: The visual texture created through the embossing process can lend itself beautifully to artistic, decorative applications. Consumer packaging—especially for gourmet products—incorporate embossed designs to convey premium quality and help catch the eye on store shelves. Lustrous embossed aluminum patterns evoke sentiments of luxury, and brands often find they can enhance presentations via elaborative designs or simple elegance.

-

Industrial Use: The durability of embossed aluminum foil makes it a favoured choice in industrial settings. It finds itself extensively woven into applications like HVAC ducting, metal insulation sheaths, and apparatus used in the aerospace sector, proving supplemental benefits such as conductivity promotion, corrosion resistance, and the efficient sealing of electrically-sensitive components.

-

Food Packaging Solutions: This type of embossed foil is integrated into aluminum trays and pans within the food service industry. Given its barrier properties coupled with structural integrity provided by embossing, this option safeguards culinary aromas and flavors whilst exerting efficacy seen in bake-and-refrigerate applications. Users are pleased with how embossed rolls safely contain heat without issue during meals’ transition from the oven to the tables.

https://www.aluminumplate.net/a/embossed-aluminium-foil-jumbo-roll.html