Mirror embossed aluminum sheet

The Reflective Edge: Mirror Embossed Aluminum Sheets

In the ever-evolving landscape of materials used across diverse industries, mirror embossed aluminum sheets have carved a unique niche. But beyond their stunning aesthetic appeal, there lies a functionality and versatility that deserves a closer look.

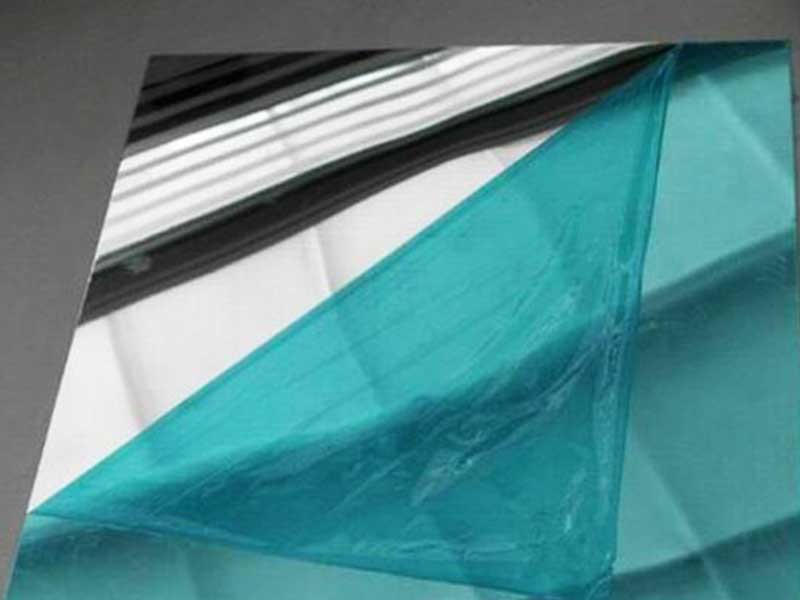

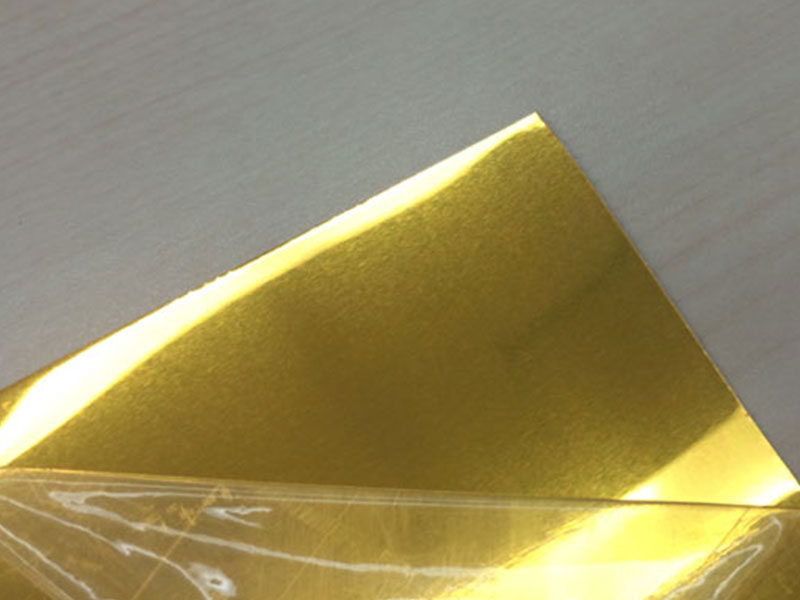

The real magic in mirror embossed aluminum sheet isn't just the shine; it's the interplay between the perfectly polished surface and the subtly textured embossing. We often get requests for incredibly specific embossing patterns – everything from delicate floral designs to geometric grids – and achieving the mirror finish after the embossing process requires meticulous control over pressure, temperature, and the chemical polishing stages. A tiny imperfection in the embossing dies can dramatically affect the final reflectivity, leading to frustrating rework. Personally, I find the most satisfying aspect is the problem-solving involved – figuring out how to coax that perfect mirrored finish out of a piece of aluminum that's been physically manipulated. It's a real testament to the precision of our equipment and the expertise of our operators.

What many customers don't appreciate is the delicate nature of the final product. That stunning mirror finish is susceptible to scratching and marring far more easily than a plain, un-embossed sheet. It's a constant balancing act; the embossing adds depth and visual interest, but it also increases the surface area prone to damage during handling and transportation. We're constantly experimenting with new protective coatings and packaging methods to minimize this, and it's a challenge I'm personally invested in. Getting a flawless sheet to the client, knowing the effort and precision that went into its creation, is the most rewarding part of my job.

The Art and Science Behind Mirror Embossed Aluminum Sheets

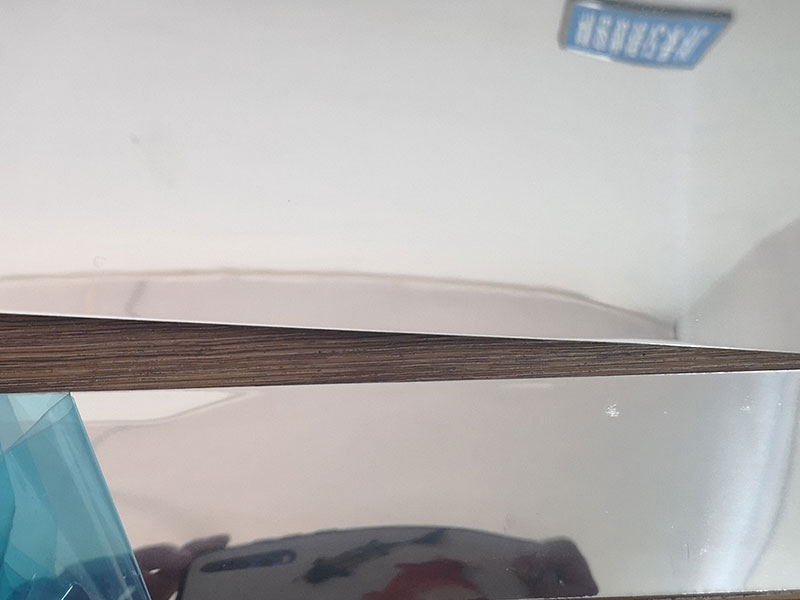

At first glance, mirror embossed aluminum sheets captivate admirers with their reflective surface, evoking images of ornamental designs and contemporary artistry. However, these sheets do not merely rely on their appearance. The process of embossing involves essentially three pivotal steps: rolling, heating, and cooling, which manipulate the aluminum into intricate patterns while simultaneously enhancing its sheen.

The trade-off often comes down to choosing a balance between sheer beauty and structural integrity. The vibrant array of textures created during this process serves both as a decorative layer and a tactic to provide the material with increased rigid support.

Applications That Go Beyond Bling

One might assume these sheets are relegated merely to decorative applications; however, their usage defies those constraints. From wall adornments in luxury hotels to fixtures in retail spaces that crave an element of extravagance, mirror embossed aluminum sheets shine in settings where first impressions count.

These sheets also prioritize cleanability and durability. Particularly in industries like food and beverage, where hygiene is paramount, the mirror finish facilitates effective cleaning routines without degrading appearance or structure. Additionally, applications can be seen within transportation, covering interiors of airplanes, auxiliary components in cars, and siding on modern vehicles that blend practicality with aesthetic advances.

A Sustainable Choice

In today’s sustainability-focused climate, the reflected brilliance of these sheets has entwined with eco-friendliness. Aluminum is extensively recycled without losing its properties, offering an appealing proposition for environmentally conscious projects. The talent lies in giving function and elegance a shared space where both can thrive sustainably.

Patterns That Narrate Growth

Mirror embossed aluminum is frequently customized to fit various diagonal patterns, which some envision resembling waves while others interpret as a reflection from a dynamic ray of light. The framing allows for better light dispersion, altering room perceptions and player dynamics in spaces like restaurant lobbies or theater auditoriums.

Ad creators and marketers delight in this potential, leveraging reflective surfaces to create memorable and engaging advertising aesthetics. Your brand can speak volumes when using materials both innovative and popular among top makers of visually striking installations.

Wrapping Up the Reflection

It’s evident: mirror embossed aluminum sheets are far more than mere vessels for reflection; they echo identity, style, and intelligence in material assembly and design. They have ineffably influenced multiple industries—from architecture to aerospace, retail to hospitality—eflecting how something so simple as an aluminum sheet can be mutable and profound.

With a global market racing toward modern designs and precise functionality, there has never been a better time to discover opportunities to integrate mirror embossed aluminum sheets into your projects. In a world pivoting continuously toward reflective experiences, these artistry-meets-utility sheets invite creatives and constructors alike to take a deeper look at our environment and materials.

https://www.aluminumplate.net/a/mirror-embossed-aluminum-sheet.html