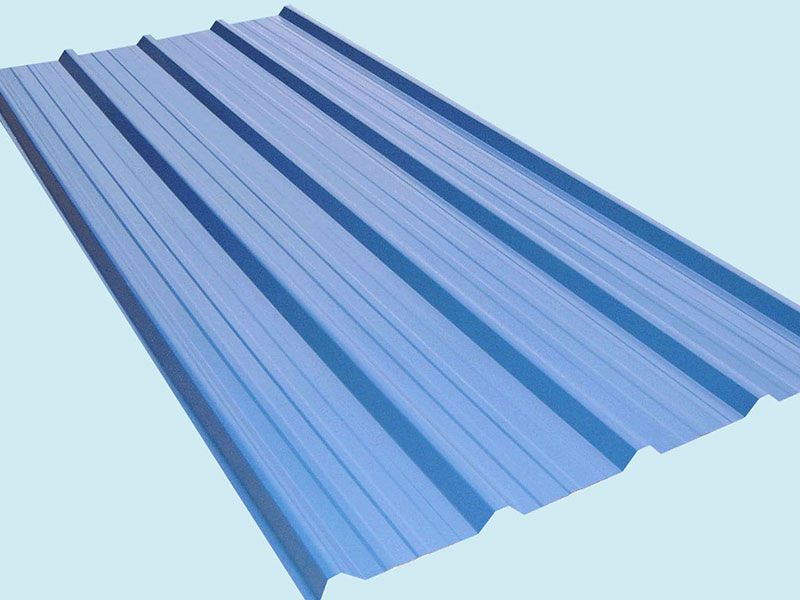

Product description: 3003 aluminum roofing sheet is becoming a popular choice for use in installations and buildings. It is corrosion-resistant in almost any kind of environment.

3003 aluminum roofing sheet is becoming a popular choice for use in installations and buildings. It is corrosion-resistant in almost any kind of environment. Even in highly-corrosive industrial environments, it is resistant to fumes and vapours of organic compounds and to chemicals like ammonia, carbon-dioxide and acids like hydrochloric acid, nitric acid and sulphuric acid. This corrosion-resistant property gives the metal a long life and keeps it looking good throughout its life.

Professional cutting line,to make sheet with any length

Embossed line could process aluminum coil with max thickness (1.0mm of A5754 H24);

Brushing line,to make the coil brushed as required;

Full-set processing for food-grade aluminum coil and sheet.

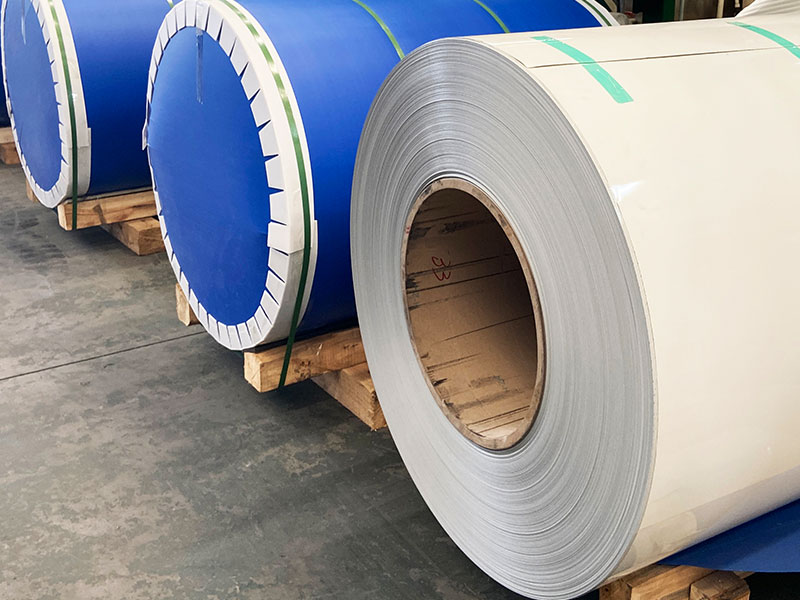

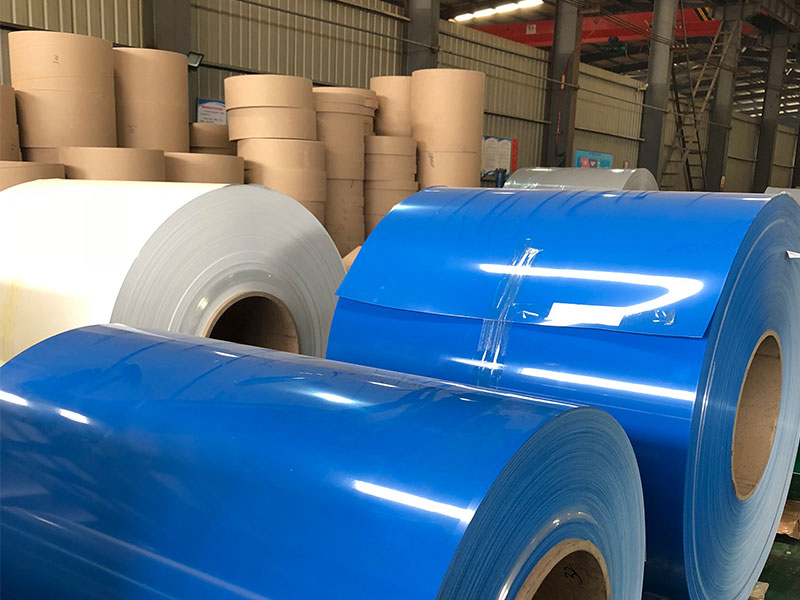

Sufficient Raw-materials in Stock 3003 aluminum roofing sheet:

To make an shorter lead-time ,lidao hold in stock around 5000tons of aluminum coil mill finishing , in alloy A1,A3, or A5 series; with thickness from 2.0mm to 3.0mm width from 1000mm to 2400mm also approx 2000tons of coated aluminum coil and sheet ,As VIP customers of our suppliers ,we could always get the raw-materials as soon as possible.

| Chemical Content | |||||||||||

| Alloy | Si | Fi | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Single | Total |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 0.03 | 0.03 | - |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | 0.03 | 0.03 | - |

| 1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | |||

| 1100 | 0.95 | 0.05-0.20 | 0.05 | - | - | - | 0.10 | - | 0.05 | 0.14 | |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | 0.05 | 0.15 |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5-1.1 | 0.10 | - | 0.25 | - | 0.05 | 0.15 |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | - | 0.10 | 0.08 | 0.05 | 0.15 |