Embossed aluminum sheet 3003 3004 3005 3104 3105 H14

Embossed aluminum sheets in alloys 3003, 3004, 3005, 3104, and 3105 processed with H14 temper represent a popular solution across industries requiring lightweight, corrosion-resistant, and aesthetically enhanced metal sheets. The embossing (sometimes called stucco embossing) improves surface properties by enhancing visual appearance and increasing slip resistance, making these sheets ideal for applications in construction, transportation, and consumer products.

What is Embossed Aluminum Sheet?

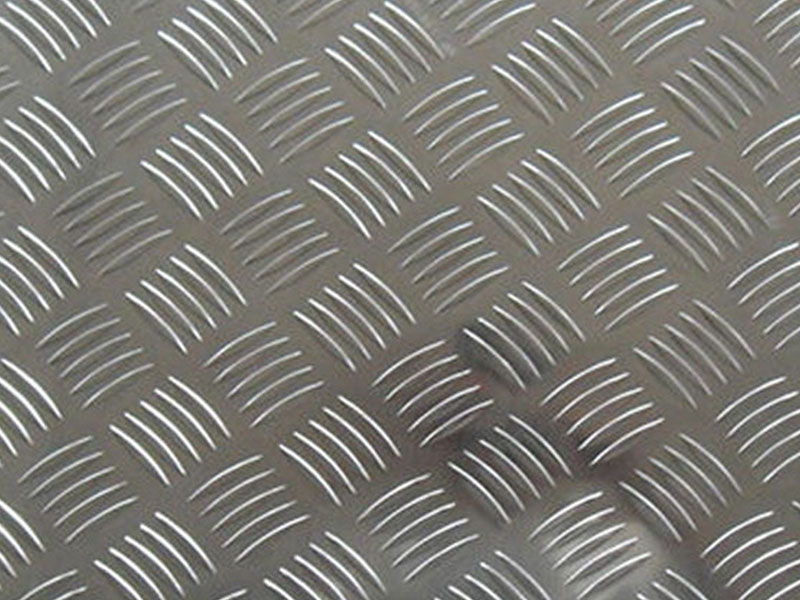

Embossed aluminum sheets feature raised or patterned surfaces created through mechanical rolling processes. Embossing modifies the flat surface by introducing patterns such as Stucco, diamond, pebble grain, or other decorative designs, which enhances not only the visual aspect but also grip and wear resistance.Applications can be broad—ranging from ceiling panels, siding, elevator cans, and exposure surfaces requiring durable yet eye-catching finishes.

Working with 3003, 3004, 3005, 3104, and 3105 H14 embossed aluminum sheets for stucco applications presents unique challenges. The H14 temper, while offering good formability for the embossing process, can also lead to inconsistencies if not handled carefully during the manufacturing stages. We've found that slight variations in the embossing pressure or die temperature can significantly impact the final texture and even lead to cracking or tearing, particularly in the thinner gauges often used in stucco. The different alloy compositions themselves also impact the embossing process; 3004, for instance, with its higher manganese content, might require slightly different parameters compared to 3003 to achieve the desired depth and clarity of the embossing. Careful monitoring of these parameters throughout the production run is crucial to maintaining consistent quality and minimizing waste.

Furthermore, the stucco application itself necessitates a robust and durable final product. The embossed surface, while aesthetically pleasing, can be prone to scratching or damage during handling and installation. We’ve learned that pre-treating the embossed sheets with a protective coating before shipping helps mitigate this issue significantly, reducing the number of customer returns due to surface damage. Additionally, the specific application requirements—such as the type of adhesive used and environmental conditions—is critical for ensuring the long-term performance and longevity of the final stucco product. Proper

The 3000-series wrought aluminum alloys listed here are principally alloyed with manganese (Mn), resulting in excellent corrosion resistance, moderate strength, and excellent formability. Variations between alloys come from subtle changes in composition that impact strength, hardness, and surface behavior.

| Alloy | Major Alloying Elements | Typical Applications |

|---|---|---|

| 3003 | 1.0-1.5% Mn | Cooking utensils, roofing, siding, storage tanks |

| 3004 | ~1.2% Mn, + <1% Mg | Decoration, high-strength architectural panels |

| 3005 | ~1.2% Mn, ~0.5% Mg | Facades, transport, roofing sheets |

| 3104 | High Si (<0.3%), 1.0%-1.5% Mn | Building facades, coke and gas fields |

| 3105 | <1.3% Mn, ~0.3-0.6% Mg | Exterior garages, mobile homes, roofing |

Chemical Composition (wt%)

| Element | 3003 | 3004 | 3005 | 3104 | 3105 |

|---|---|---|---|---|---|

| Aluminum (Al) | Balance | Balance | Balance | Balance | Balance |

| Manganese (Mn) | 1.0-1.5% | 1.0-1.5% | 1.0-1.5% | 1.0-1.5% | 0.7-1.3% |

| Magnesium (Mg) | 0.05-0.20% | 0.2-0.7% | 0.4-0.7% | 0.20-0.8% | 0.3-0.6% |

| Silicon (Si) | ≤0.6% | ≤0.8% | ≤0.6% | ≤0.3% | ≤0.3% |

| Iron (Fe) | ≤0.7% | ≤0.7% | ≤0.7% | ≤0.7% | ≤0.7% |

Note: The percentages can have slight variations depending on accordance with international standards.

Mechanical Properties and Temper H14

The designation H14 temper indicates that the aluminum sheet is strain hardened and partially annealed. This provides good strength with moderate ductility, better shaping ability than fully hardened alloys (H18), while offering higher strength than fully annealed (O temper).

| Property | Typical Values | Test Standard |

|---|---|---|

| Tensile Strength | 145-180 MPa | ASTM B209 / EN 485-2 |

| Yield Strength | ~110-140 MPa | ASTM B209 / EN 485-2 |

| Elongation (%) | 3% - 7% | ASTM B209 / EN 485-2 |

| Hardness (Brinell) | ~45-60 HB | ASTM E10 |

| Density | 2.7 g/cm³ |

Standards and Compliance

Most embossed aluminum sheets in these alloys and temper conform with the following standards:

- ASTM B209 – Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485-2 – General mechanical properties of aluminum alloy products

- JIS H4000 Series – Japanese standards on aluminum sheets and plates

- GB/T 3190 – Chromatography chemical composition specifications for aluminum alloys from China

These standards ensure that the embossed sheets maintain consistent mechanical and chemical characteristics essential for demanding industrial use.

- Casting and Hot Rolling: Continuous casting of basic alloy billets moves through hot rolling into thick plates or coils.

- Cold Rolling: Processed as full thickness cold rolled coils with controlled thickness tolerances.

- Annealing: Softening step to adjust grain structures before final temper rolling.

- Final Temper Rolling (H14): Partial strain hardening creates the required strength profile perfect for embossing.

- Embossing: Rolling through patterned rollers imprints desired textures (stucco or custom designs).

- Cutting and Finishing: Cut to required sizes, inspected, and packed.

Applications

- Architecture: Facades, roofing panels, soffits, elevator interiors

- Consumer Goods: Kitchen utensils, vending machines, lighter-weight appliances

- Transport: Truck/trailer bodies, camper shells, med offices

- Industrial: Chemical tanks, compressors, decorative ceilings

Embossed aluminum sheet in 3000-series alloys with H14 temper serves industries that require enhanced aesthetic appeal combined with unmatched corrosion resistance.

- Embossed aluminum sheets in alloys 3003, 3004, 3005, 3104, and 3105 offer optimal strength, improved handling, and decorative surfaces with H14 temper partial-hardening.

- Common in architectural, transport, and household usages, these materials fulfill performance needed for wide environments.

- Selecting the right alloy and emboss pattern allows balancing manufacturability, appearance, and overall durability.

For demand inquiries, tailor-made embossings, or technical consultations on embossed aluminum sheets 3003, 3004, 3005, 3104, 3105 H14, contact our expert team.

Keywords: Stucco Embossed Aluminum Sheet, 3003 Aluminum, 3004 embossed aluminum, H14 temper aluminum rolling, decorative aluminum sheet, embossed reroofing aluminum panel

https://www.aluminumplate.net/a/embossed-aluminum-sheet-3003-3004-3005-3104-3105-h14.html