Mirror Finislh Anodized Aluminum Sheet

Mirror Finish Anodized Aluminum Sheet: The Perfect Fusion of Aesthetic Brilliance and Technical Excellence

In the world of architectural design and industrial applications, surface finish and durability often dictate the material’s suitability. Among numerous options, the Mirror Finish Anodized Aluminum Sheet stands out—not just for its reflective, lustrous beauty but also its enhanced technical attributes. As experts in aluminum alloys, we delve beneath the surface to elucidate why this material represents an unparalleled choice for projects demanding both elegance and engineering resilience.

What is a Mirror Finish Anodized Aluminum Sheet?

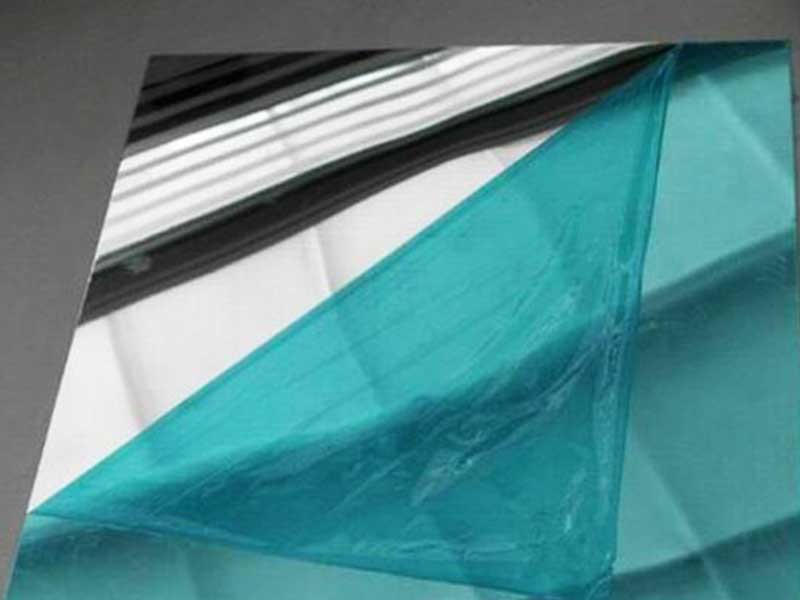

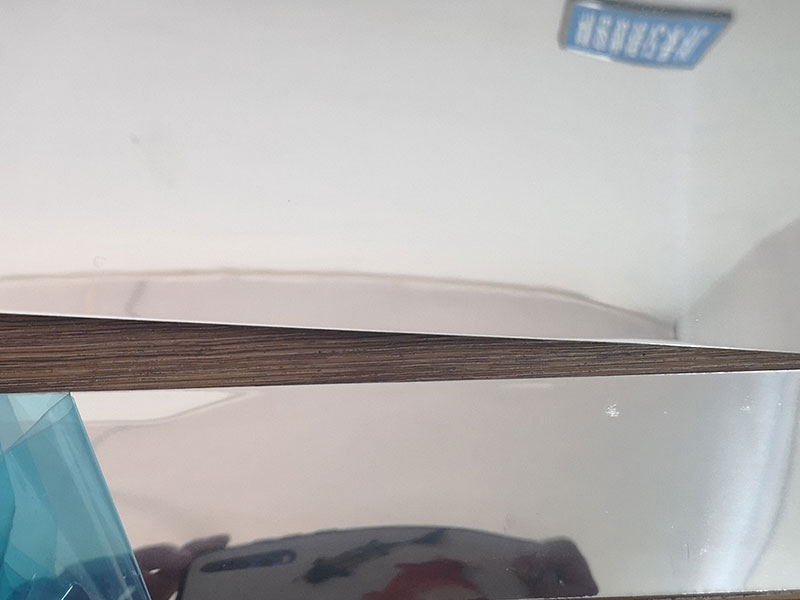

At first glance, a Mirror Finish Anodized Aluminum Sheet is aluminum meticulously polished to a near-perfect reflective surface and then treated through anodization—a sophisticated electrochemical process forming a protective oxide layer on the metal’s surface. The hybrid of this mirror-like polish and a fortified anodic layer simultaneously elevates its appearance and extends its lifecycle.

Technical Nuances from a Unique Viewpoint

1. Anodization: More Than Just Protection

Unlike simple polishing, anodization transforms aluminum through controlled oxidation, thickening its natural oxide layer. This makes the mirror surface resistant to abrasion, corrosion, UV rays, and chemical impacts—properties essential for outdoor and high-demand environments. From an engineering perspective, anodization is the meticulous creation of a nano-porous surface structure that seals the microscopic scratch vulnerabilities common in regularly polished metals.

2. Surface Reflection and Light Interaction

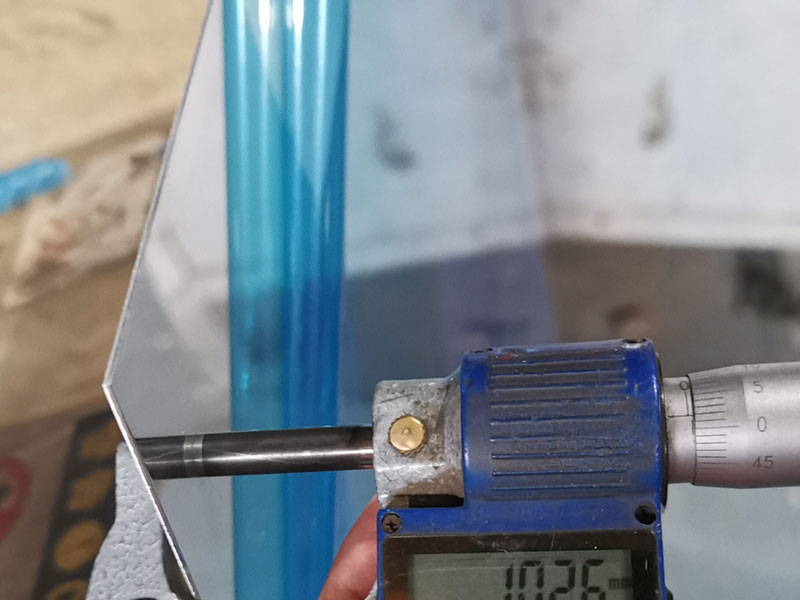

The polishing process employed to achieve a mirror finish involves precision grinding and buffing stages that yield a surface roughness with nanoscale evenness. This ultra-smooth surface enables sunlight or artificial lighting to bounce off with minimal scatter, amplifying visibility and making it an ideal choice for decorative cladding, signage, or interior accents where vibration-free reflections are crucial.

3. Thermal Management

Unbeknownst to many, the anodized layer significantly influences the thermal emissivity of aluminum. For applications like heat exchangers or LED reflectors, the Mirror Finish Anodized Aluminum Sheet balances high light reflectivity with controlled thermal conductivity, meaning it helps in dissipating heat while maintaining aesthetic clarity. This dual functionality is the hallmark advantage in electronic housings and lighting fixtures.

4. Environmental Sustainability

The anodizing electrolyte and subsequent rinse waters are treated and recycled with modern green technologies during production. Furthermore, anodized mirror aluminum sheets prolong service life dramatically, reducing the need for replacements and conserving raw materials. Their recyclability post-application contributes positively to a closed-loop economy.

Ideal Applications Driving Demand

- Architectural Elements: Glass facades, decorative elevator panels, and ceiling tiles capitalize on the bright mirror sheen while benefiting from corrosion resistance.

- Transportation: Luxury vehicle trim and aviation interiors leverage both the beauty and the lightweight endurance.

- Interior Design: Furniture hardware and appliance exteriors maintain freshness without additional coatings deteriorating over time.

- Electronics & Lighting: As premium reflectors, they optimize lumen output and enhance device performance.

https://www.aluminumplate.net/a/mirror-finislh-anodized-aluminum-sheet.html