Aluminum tread plate 1100 H16 Stucco Color Coated Embossed

Aluminum tread plate 1100 H16 stucco color coated embossed sounds like a long technical phrase, but behind it is a simple idea: a lightweight, corrosion‑resistant aluminum sheet with a textured, decorative surface and protective color coating, designed to perform reliably in demanding environments while still looking good.

This material is widely used in building facades, interior decoration, cold rooms, transport, and equipment cladding. what each part of the name means helps you see whether it fits your project.

What “1100 H16 Stucco Color Coated Embossed” Really Means

The description can be broken into four dimensions: alloy, temper, surface texture, and coating.

Alloy 1100

Alloy 1100 is commercially pure aluminum, typically containing 99.0% or more aluminum. It is known for:

- Excellent corrosion resistance, especially in atmospheric and marine environments

- Very good thermal and electrical conductivity

- High formability and weldability

- Non‑heat‑treatable behavior (strength is achieved by cold working, not heat treatment)

Because it is so pure, 1100 is softer than alloys like 3003 or 5052. That makes it ideal when you need easy bending, stamping, or forming, and you do not require high structural strength. For a tread plate or embossed sheet, this softness is actually helpful: the embossing is more uniform and consistent, and the sheet is easier to process on site.

Temper H16

The temper code tells you how the aluminum has been strengthened.

- “H” means strain‑hardened (cold worked)

- The first digit “1” indicates strain‑hardened only, without additional thermal treatment

- The second digit “6” denotes a degree of hardness roughly equivalent to “half‑hard plus” (between H14 and H18 in strength)

In practice, 1100 H16 is:

- Stronger and stiffer than fully annealed 1100‑O

- Still workable enough to be bent, roll‑formed, and lightly deep‑drawn

- Stable under normal service temperatures; it does not rely on heat treatment for its properties

For applications like wall cladding, interior panels, ceiling tiles, and equipment covers, H16 gives a good balance: enough rigidity to hold shape, light enough to handle easily, and not so hard that it cracks during forming.

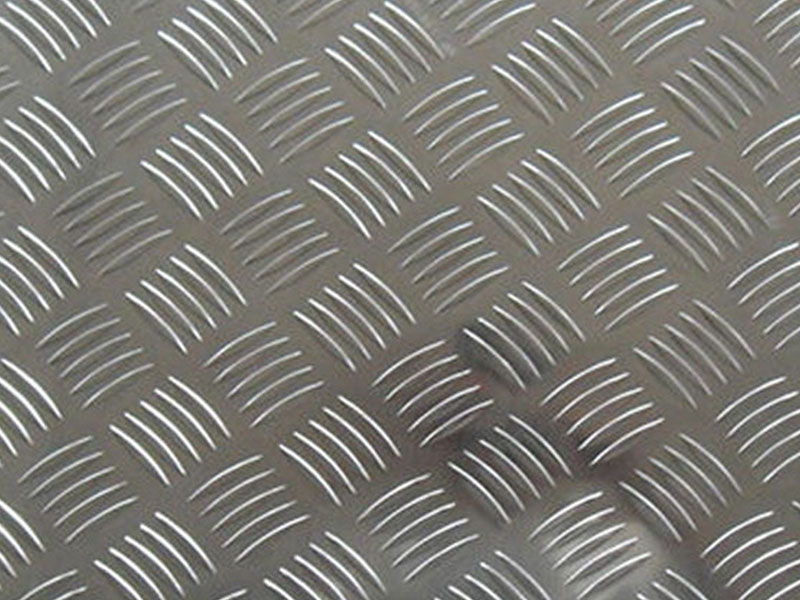

Stucco Embossed Texture

The “stucco” term refers to a random, orange‑peel‑like texture pressed into the surface. This is not a raised diamond tread pattern, but a small‑scale, irregular embossing. The effect is both functional and aesthetic:

- It scatters light, reducing glare and giving a soft, matte reflection

- It hides fingerprints, small dents, scratches, and minor installation damage

- It makes the panel appear thicker and more substantial, even when the gauge is relatively thin

- It can slightly increase stiffness thanks to the patterned surface

For architects, interior designers, and equipment manufacturers, stucco embossed plate delivers a clean but textured appearance which pairs well with color coatings and integrates easily into modern designs.

Color Coated Finish

“Color coated” normally means an organic coating (paint) baked onto the aluminum coil before forming. Common systems include:

- Polyester (PE) coatings: good gloss and color options, cost‑effective

- High‑durability polyester (HDP): improved weathering resistance

- Polyvinylidene fluoride (PVDF): premium UV and chemical resistance, used for high‑end architectural facades

The coil coating process typically involves:

- Surface cleaning and degreasing

- Chemical pre‑treatment / conversion coating for adhesion and corrosion resistance

- Primer coat

- Top coat (and optionally a back coat)

- Curing in a controlled oven for consistent film quality

Color coating turns functional aluminum sheet into a finished cladding material. It protects against weathering, improves resistance to staining and corrosion, and delivers consistent color across large facade or interior surfaces.

Typical Product Parameters

Although the exact numbers vary by manufacturer, 1100 H16 stucco color coated embossed tread plate is commonly supplied with the following ranges:

- Thickness: approximately 0.25–1.5 mm for decorative and cladding uses

- Width: up to around 1600 mm, depending on mill capability

- Coil inner diameter: usually 505 mm or 610 mm

- Coating thickness:

- Top side: about 20–25 μm for PE, 25–28 μm or more for PVDF

- Back side: 5–10 μm service coat or primer

- Surface finish: front side color coated and stucco embossed, back side plain or lightly coated

- Protective film: optional PE protective film to prevent scratches during transport and installation

Flatness, gloss level, and color tolerance are normally controlled tightly, especially for architectural applications where panels must match across an entire building elevation.

Chemical Composition of Alloy 1100

The purity of 1100 is what defines its properties. Typical composition limits are shown below (values are approximate, in percent by weight):

| Element | Typical Range (%) |

|---|---|

| Aluminum (Al) | ≥ 99.0 |

| Copper (Cu) | 0.05 – 0.20 |

| Iron (Fe) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.25 |

| Manganese (Mn) | ≤ 0.05 |

| Zinc (Zn) | ≤ 0.10 |

| Others, each | ≤ 0.05 |

| Others, total | ≤ 0.15 |

The low alloying content gives 1100 its excellent corrosion resistance and formability. The small copper addition slightly improves strength without significantly compromising corrosion behavior in typical atmospheric conditions.

Mechanical and Physical Properties in H16 Temper

Again, values depend on thickness and supplier, but typical properties for 1100 H16 sheet are:

- Tensile strength: roughly 150–195 MPa

- Yield strength (0.2% offset): around 120–160 MPa

- Elongation: about 4–10% (depending on thickness)

- Density: about 2.71 g/cm³

- Thermal conductivity: approximately 220 W/m·K

- Electrical conductivity: around 57% IACS (International Annealed Copper Standard)

- Melting range: about 643–657 °C

This profile suits non‑structural applications where light weight, corrosion resistance, and formability matter more than high load‑bearing capacity.

Implementation Standards and Quality Control

To ensure compatibility and reliability, 1100 H16 stucco color coated embossed plate is usually produced and inspected under recognized standards, such as:

- EN, ASTM, or equivalent national aluminum standards for alloy designation and mechanical properties

- Coil coating standards for film thickness, adhesion, hardness, and weather resistance

- Color standards such as RAL or custom color systems for consistency

performance checks typically include:

- Thickness tolerance and flatness

- Stucco pattern uniformity and embossing depth

- Coating adhesion (cross‑cut tests), pencil hardness, impact resistance

- Gloss level and color deviation

- Resistance to salt spray and humidity (for exterior‑grade products)

For customers, asking for certificates of conformity and test reports aligned with known standards is the fastest way to confirm product quality.

Where This Material Makes Sense

Aluminum tread plate 1100 H16 stucco color coated embossed fills a specific niche where looks, corrosion resistance, and ease of fabrication are more important than high strength. It is well suited for:

- Building facades and curtain walls, especially in non‑structural cladding zones

- Interior wall panels, column covers, ceilings, and decorative strips

- Cold rooms, food‑processing plants, and refrigeration equipment where cleanability and hygiene are

- Air‑conditioning housings, ventilation ducts, and machinery enclosures

- Vehicle and trailer interior liners (walls and ceilings rather than heavy‑duty floors)

The embossed pattern hides imperfections and dirt, the coating provides color and added durability, and the 1100 alloy base keeps weight low and machining simple.

Why Choose 1100 H16 Stucco Color Coated Embossed Plate

From a practical purchasing perspective, this material offers a combination of advantages:

- Lightweight but stiff enough for panel applications

- Highly resistant to atmospheric corrosion without heavy maintenance

- Easy to cut, fold, and shape during fabrication or on site

- Attractive, glare‑reducing textured surface that stays cleaner in appearance

- Wide color range, with options from economical PE to long‑life PVDF systems

- Consistent quality thanks to modern coil coating and embossing processes

For designers and buyers who need a visually appealing aluminum surface that installs easily and performs reliably in everyday use, 1100 H16 stucco color coated embossed tread plate is a straightforward, proven choice.

https://www.aluminumplate.net/a/aluminum-tread-plate-1100-h16-stucco-color-coated-embossed.html