Chemical Free CTP Plate for Kodak CTP machine

In the realm of modern printing technology, the continuous evolution of plate-making solutions is redefining traditional paradigms. Among the innovations capturing attention is the Chemical Free CTP Plate, specifically designed for Kodak CTP (Computer-to-Plate) machines. These plates have not only transformed how print houses operate but also signified an important shift towards sustainable practices in the industry.

What are Chemical Free CTP Plates?

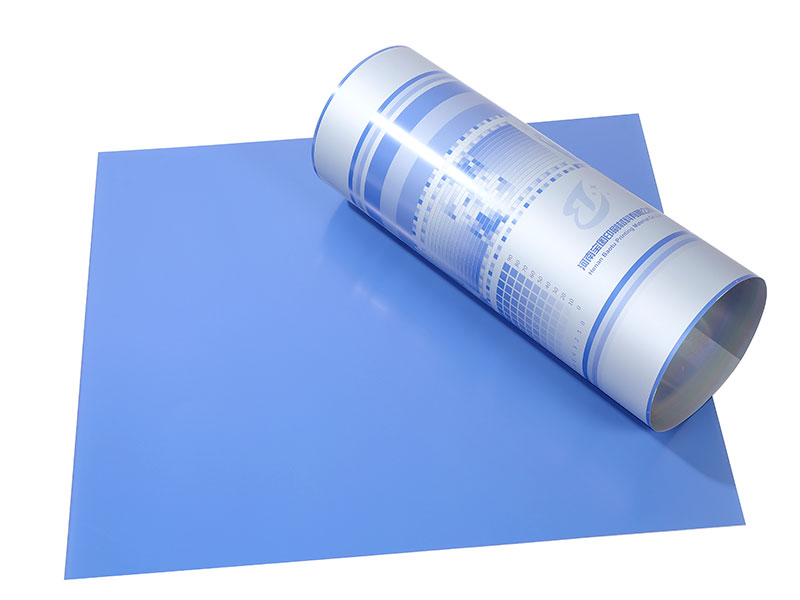

Chemical Free CTP Plates are specially engineered printing plates that eliminate the need for harsh chemicals typically required during the pre-press stage known as plate developing. Instead, these plates can be processed using basic water procedures, reducing environmental hazards, improving safety for operational staff, and lowering the overall footprint of the printing process.

The Advantages of Chemical Free Technology for Kodak Machines

1. Simplicity in Processing

Using Chemical Free CTP Plates allows for a streamlined workflow when integrated with Kodak CTP machines. By merging user-friendly technology with conference-quality results, print service providers can simplify their operations. The ease of using these plates means there’s potential for fewer errors during production, thus elevating overall print quality.

2. Environmentally Sound

As climate change and resource conservation grow more urgent in discussion, packaging manufacturers are focusing on sustainability strategies. The implementation of Chemical Free plates not only eliminates harmful waste associated with traditional development chemicals but also uses less water, making a considerable enhancement to environmental performance.

3. Achieving Superior Print Quality

Users of Kodak CTP systems will be pleased to note that these Chemical Free plates deliver exceptional quality akin to conventional thermal plates. They exhibit excellent resolution, consistency, finishing robustness, and wider color gamuts, making them suitable for challenging printing tasks while also preserving details in both text and imagery.

Parameters and Standards

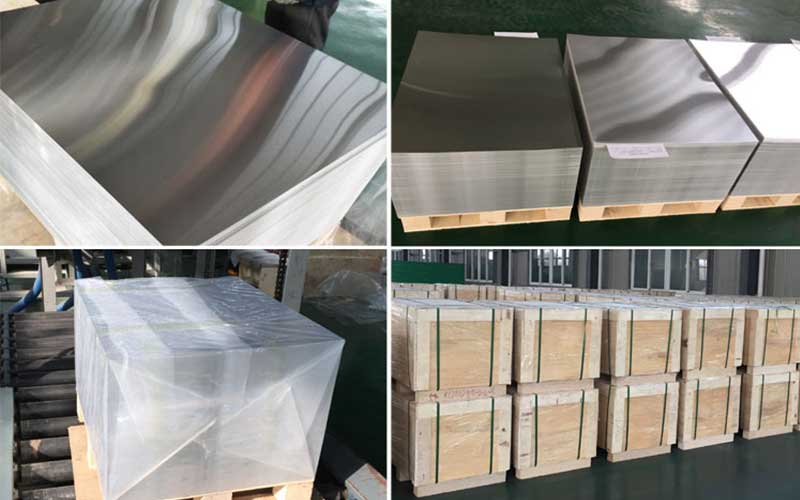

Utilizing Chemical Free CTP Plates involves careful sensitivity to a variety of specifications and standards to guarantee consistent performance and longevity. Below is a comprehensive overview of critical mechanical and technical parameters.

| Parameters | Specifications |

|---|---|

| Plate Thickness | 0.15 mm, 0.20 mm, 0.30 mm |

| Light Sensitivity | 830 (macro handling LEDs) |

| Resolution | Up to 2400 dpi |

| Contrast Ratio | Excellent (ratio > 4:1) |

| Run Length | Up to 100,000 impressions |

| Printing Speed | Compatible up to 3000 sph |

| Developing Method | Water wash (solutions) |

| Storage Conditions | Below 25 °C, away from light |

Alloy Tempering and Chemical Properties

The innovation lies within the effective blending of aluminum alloy attributes. Chemical Free CTP plates leverage an advanced blend of aluminum alloys conducive to tapering for high durability enabling prolonged lifetimes which reduces waste. the characteristics of these alloys can help print manufacturers select the ideal solutions for their business requirements.

Studies show specific compositional characteristics including Alloy Temper, showed proficiency in performance and bonding strength assisting adequately during plate exposure and developing stages—common alloys include:

| Properties | Aluminum 7050 Alloy | Aluminum 6061 Alloy |

|---|---|---|

| Yield Strength | High (up to 500 MPa) | Moderate (260 MPa) |

| Corrosion Resistance | Excellent | Moderate |

| Temper & Finish | T7451 Prepare Finish | T6 Normal Milled |

| Weight Saving Factor | Heavy applications | Widespread versatility |

While evaluating the use of Chemical Free CTP plates in Kodak CTP machines, it is essential for print operations to interpret which properties meet requirements for practical interoperability.

Final Thoughts

The evolution from traditional plate technology to adopting a chemical-free approach marks a significant advancement in not only satisfying commercial mandates but also promoting ecological responsibility. The dialogue surrounding the versatility of Chemical Free CTP plates for Kodak CTP machines positively influences cost-effectiveness, reversing environmental impacts prevalent in the printing industry.

As we foster a landscape driven by innovation and sustainability in printing practices, Chemical Free CTP plates are trailblazing routes toward optimization unmatched by traditional options. By bridging inessentials of superior print technology with eco-conscious methods, the printing industry is on the cusp of a transformative epoch that embraces the sustenance of fruitful practices marginal dated paradigms elegantly and seamlessly into the practices of the future.

https://www.aluminumplate.net/a/chemical-free-ctp-plate-for-kodak-ctp-machine.html