Alloy 1050 Solar Mirror Finish Aluminum

As the global push for renewable energy sources intensifies, materials that drive efficiency and innovation are at the forefront of solar technology advancements. One such material gaining remarkable acclaim is Alloy 1050 Solar Mirror Finish Aluminum. Standing out with its purity and enhanced reflective properties, this alloy embodies an ideal blending of aesthetics and functionality tailored for solar energy applications. Let's dive into the unique characteristics and technical details that make this alloy a game changer for the solar industry.

Alloy 1050

Aluminum alloys are categorized by their primary alloying elements, with 1050 being predominantly of high purity (99.5% aluminum or higher). What makes this alloy particularly pertinent to solar technology is its combination of lightweight properties, flexibility, and excellent resistance to corrosion.

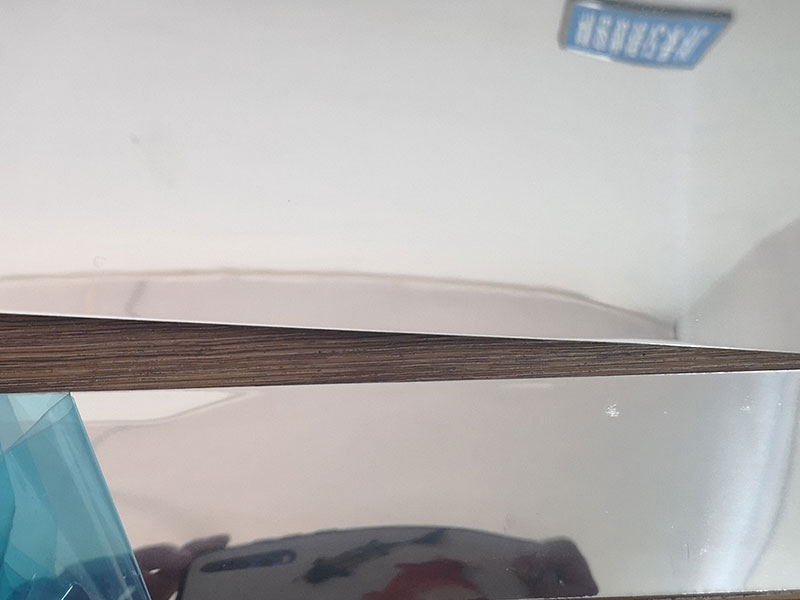

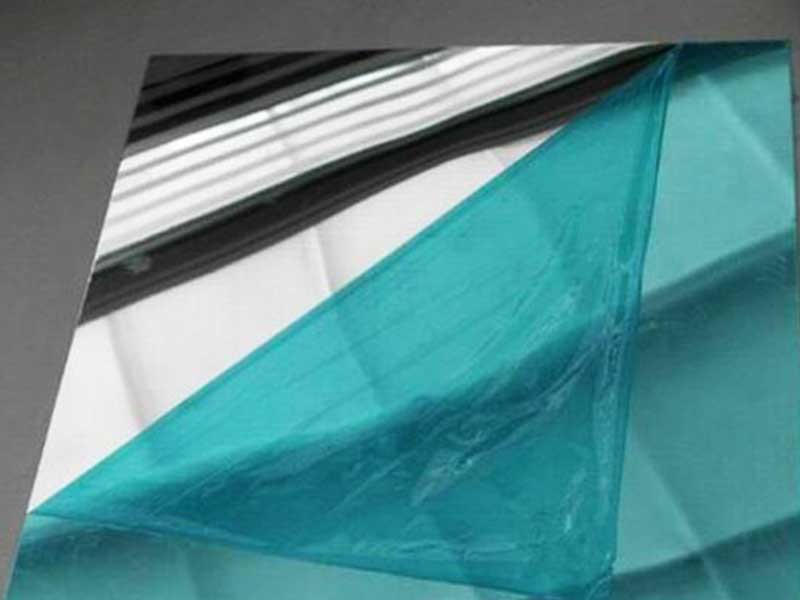

Alloy 1050, with its solar mirror finish, presents a unique set of challenges and advantages in our Mirror Aluminum Sheet production. Its high purity and excellent reflectivity make it ideal for solar applications, demanding tight tolerances on surface finish and minimal imperfections. However, the very properties that make it desirable also increase its susceptibility to scratching and marring during processing. We've found that optimizing our handling procedures, from coil unwinding to final packaging, is crucial to prevent surface defects. Specifically, minimizing contact with abrasive materials, controlling humidity to prevent oxidation, and employing specialized rollers during the levelling and polishing stages are to maintaining the superior reflectivity demanded by our clients. Careful selection and consistent maintenance of our equipment is equally important to prevent the introduction of surface flaws which would otherwise compromise the product's performance.

Beyond the production challenges, a insight is the importance of thorough quality control at each stage. We utilize advanced surface inspection techniques, including laser scanning and microscopic analysis, to identify even minute imperfections that could detract from the mirror finish. Furthermore, rigorous testing for reflectivity and durability ensures consistent performance and meets the stringent requirements of our customers in the solar energy sector. The payoff, however, is significant. Producing high-quality 1050 solar mirror aluminum sheet not only contributes to a more efficient and sustainable energy sector, but also reinforces our factory's reputation for precision and expertise in the specialized field of aluminum sheet production.

Unlike its more complex counterparts in the 3000 or 5000 series, Alloy 1050 is straightforward—a quality that offers sustainability from both a manufacturing and performance perspective. The use of less energy during its production cycle directly reduces greenhouse gas emissions, promoting a cleaner planet in accordance with global environmental goals.

Reflective Superiority and Energy Efficiency

When it comes to solar energy generation, the effectiveness of solar mirrors and reflective panels is paramount. Alloy 1050's exceptional solar mirror finish offers unmatched reflectivity, essential for maximizing light absorption through mirror polished surfaces.

Each sheet of Alloy 1050 is engineered to minimize light dispersion with a maximum reflectance rating, making it crucial in concentrating solar power systems. By optimizing light energy capture, the Alloy 1050 solar mirror sheets significantly increase energy efficiency. This convergence of innovation not only ensures a higher performance output but does so in a lightweight manner, allowing for easier application onto various substrates without compromising structural integrity.

Application in Modern Solar Technologies

The versatility of Alloy 1050 is evident in various real-world applications, from consumer-grade solar thermal collectors to large-scale solar plants. As developers forgo traditional, heavier materials like glass, the move toward these mirror-finish aluminum sheets allows for streamlined installation processes while ensuring long-term reflective properties.

Emphasizing Responsiveness in Design

Designers looking to capitalize on renewable technologies are drawn to Alloy 1050 for its malleability. This alloy can be easily cut into custom shapes, enabling a higher level of design responsiveness in constructing solar skytraps, parabolic mirrors, and heliostats. The possibility of tailoring sizes helps optimize performance while shedding unnecessary weight, creating unhindered efficiency reminiscent of the working principles of modular range design.

Eco-Friendly Benefits

In a world of increasing demand for green solutions, Alloy 1050 embodies recyclable properties that are pivotal for a sustainable future. The manufacturing process encompasses environmentally friendly protocols, and upon serving its purpose, misuse can be recycled into new applications without losing its rich impurities or properties.

Not to mention its longevity-fueled lifespan transforming into remarkable economic benefits expands its eco-label while powering technology-to-technology corrections—resulting in positive impacts on both the environment budget across industries, bridging a commonality between procedure and goodwill-conscious forward thinking.

https://www.aluminumplate.net/a/alloy-1050-solar-mirror-finish-aluminum.html